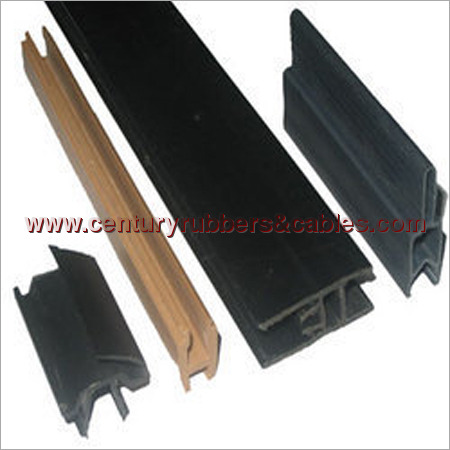

Extrusion Rubber Parts

Product Details:

- Material EPDM, NR, NBR, SBR, Silicone, Neoprene

- Tolerance 0.2 mm

- Part Type Extruded Rubber Profiles/ Sections

- Color Black (custom colors available)

- Resistance level Ozone, Weather, Oil, and Chemical Resistant

- Width Customizable; typically 5 mm to 100 mm

- Style Solid/ Hollow/ Profile Extrusions

- Click to View more

Extrusion Rubber Parts Price And Quantity

- 100 Piece

- 4-1000 INR/Piece

Extrusion Rubber Parts Product Specifications

- Low

- Available as per specification

- Extrusion Rubber Parts

- Up to 50 meters (coil form)

- Less than 2%

- Automotive industry, Electrical enclosures, Construction, Industrial machinery, Sealing and gasketing, Vibration damping

- Less than 5%

- Variable as per size and length

- Available on request

- 1 mm to 20 mm

- Rubber Material Only

- EPDM, NR, NBR, SBR, Silicone, Neoprene

- Customizable; typically 5 mm to 100 mm

- Ozone, Weather, Oil, and Chemical Resistant

- Smooth/ Textured

- Approx. 0.13 W/mK

- Solid/ Hollow/ Profile Extrusions

- Flexible, Weather resistant, Durable, UV Stable

- As per client requirement

- Up to 50 mm or as per design

- Black (custom colors available)

- Extruded Rubber Profiles/ Sections

- EPDM, NR, NBR, SBR, Silicone, Neoprene

- 0.2 mm

Extrusion Rubber Parts Trade Information

- 1000 Piece Per Day

- 1 Days

Product Description

Extrusion Rubber Parts

With the help our hard-working professionals, we are engaged in manufacturing, exporting and supplying quality proven range of Extrusion Rubber Parts. Fabricated using top grade rubber, we make sure that the manufacturing is done in compliance with standard quality standards. Our offered products are widely demanded owing to its high quality, durability and resistance to various harsh conditions. These Extrusion Rubber Parts are available in various specifications and can be customized as per the requirements of our respected customers.

Specification

| Hardness | 20-70 shore A |

| Usage/Application | Industrial |

| Color | Black,white,gray |

| Material | Rubber |

| Temperature Range | -40 to 140 centigrade degree |

| Shape | Rectangular |

Versatile Design & Customization

Choose from solid, hollow, or specialized profile extrusions in customizable widths (5100 mm), thicknesses (120 mm), and lengths up to 50 meters per coil. Parts can be tailored to meet unique application demands based on client drawings or samples, ensuring an accurate fit every time.

Superior Performance & Material Options

Featuring high weather, UV, ozone, oil, and chemical resistance, these extruded rubber profiles are manufactured using your choice of EPDM, NR, NBR, SBR, Silicone, or Neoprene. Each option delivers specific benefits in electrical insulation, durability, and environmental stability, and flame resistance is also available on request.

Applications Across Industries

Our rubber extrusions are designed for diverse uses in the automotive, electrical enclosure, construction, and industrial machinery sectors. Their propertiessuch as flexibility, low water absorption, and effective vibration dampingmake them ideal for sealing, gasketing, and protective applications even in harsh environments.

FAQs of Extrusion Rubber Parts:

Q: How are extrusion rubber parts customized for specific projects?

A: Customization is available based on detailed client drawings or physical samples. Dimensions such as width (5100 mm), thickness (120 mm), and profile shape can be tailored to fit the requirements of your application, ensuring an optimal fit and performance.Q: What materials are available for these extruded rubber parts, and how do they affect performance?

A: We offer EPDM, NR, NBR, SBR, Silicone, and Neoprene rubbers, each with unique strengths. EPDM, for example, provides excellent UV and weather resistance, while NBR is ideal for oil resistance. Material choice impacts insulation level, durability, and suitability for specialized environments.Q: When should I consider using these rubber extrusions in my applications?

A: Our extrusion rubber parts are suitable anytime you require reliable sealing, vibration damping, or environmental protection, particularly in automotive, electrical, construction, or industrial machinery settings. High UV and weather resistance make them perfect for both indoor and outdoor use.Q: Where can these extrusion rubber parts be installed and how straightforward is the process?

A: They are commonly installed in automobiles, electrical enclosures, industrial equipment, and building projects. These parts are designed for easy cutting, fitting, and installation, allowing for efficient implementation across multiple industries.Q: What is the typical process for ordering and receiving custom extruded rubber profiles?

A: Start by providing your technical drawing or sample to the manufacturer. After confirming specifications, MOQ is determined as per the policy. Once approved, production and delivery timelines are communicated, ensuring fulfillment according to client needs.Q: What are the main benefits of choosing these extruded rubber parts?

A: Key advantages include outstanding weather and UV resistance, customizable profiles, low compression set, good electrical insulation, and flexibility. The parts are durable and perform well across a wide temperature and environmental spectrum, making them extremely versatile.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+