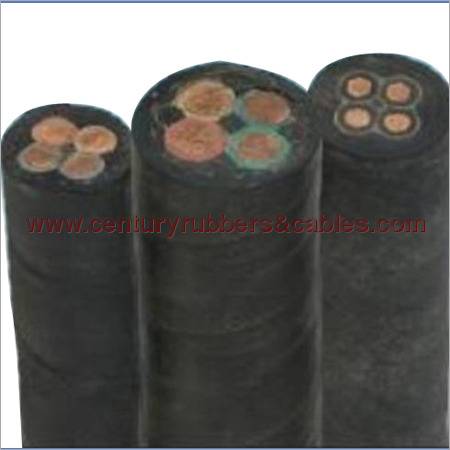

Elastomeric Cables

4-1000 INR/Meter

Product Details:

- Conductor Shape Round, flexible

- Insulation EPR/EPDM/Elastomer

- Usage & Applications Mining, Power Cables, Drilling, Welding, Portable equipment

- Dielectiric Strength 2.5 kV for 5 mins

- Core Material Annealed copper

- Weight Depends on size & no. of cores

- Tensile Strength 12 N/mm minimum

- Click to View more

X

Elastomeric Cables Price And Quantity

- 100 Meter

- 4-1000 INR/Meter

- Available

- 6x Cable OD (minimum)

- Yes

- Yes (as per IS:6380)

- Good (applicable to acids, alkalis, grease)

- Coils, Wooden Drums, as per order

- Yes

- IS 9968, IS 14494, BS 6500, IEC 60245, VDE 0282, as applicable

- As per IS/IEC standards for size

Elastomeric Cables Product Specifications

- Stranded/flexible

- Elastomeric compound (Rubber, EPDM, CSP, PCP)

- Rubber, Copper, Elastomeric compounds

- Industrial power transmission, mobile equipment, mining, general wiring

- Variable, based on type & size

- Black (standard, others available upon request)

- 100 meters (custom lengths available)

- Up to 1100V

- 2 Core, 3 Core, 4 Core, up to 61 Core

- Varies as per cable design/spec.

- 0.5 sq.mm to 300 sq.mm

- High flexibility, Abrasion resistant, Weather & oil resistant, Flame retardant, Heat resistant, Halogen free options available

- Outdoor/Indoor, Mobile/Fixed

- Flexible/Rubber Insulated Cable

- Electrolytic grade annealed copper

- Elastomeric Flexible Cable

- 12 N/mm minimum

- Depends on size & no. of cores

- Elastomer (EPR/EPDM/Rubber)

- 2.5 kV for 5 mins

- Annealed copper

- Mining, Power Cables, Drilling, Welding, Portable equipment

- As per cable configuration/specification

- EPR/EPDM/Elastomer

- Black (others customizable)

- Round, flexible

- Available

- 6x Cable OD (minimum)

- Yes

- Yes (as per IS:6380)

- Good (applicable to acids, alkalis, grease)

- Coils, Wooden Drums, as per order

- Yes

- IS 9968, IS 14494, BS 6500, IEC 60245, VDE 0282, as applicable

- As per IS/IEC standards for size

Elastomeric Cables Trade Information

- 50000 Meter Per Month

- 2 Week

Product Description

The goodwill, we have earned in the electronic market is owing to high quality Elastomeric Cables that is manufactured using latest technology and best quality materials. Our range is widely acclaimed by our clients for its outstanding attributes such as high efficiency, flexibility, high durability, acute bending radius and resistance to heat, oil, flames and ozone. Widely used in material handling applications, our customers can avail this range of Elastomeric Flexible Trailing Cables at market leading prices.

Further details

Some of the material used in developing this quality product line are listed below:

- Polypropylene

- Chloro-Sulphoneted Polyethylene (CSP)

- Nitirile Rubber/ PVC blends

- Ethylene Propylene (EPDM)

- Polychloroprene (PCP) Neoprene

Designed for Tough Industrial Environments

These elastomeric cables are engineered to withstand harsh operating conditions common in mining, construction, and power industries. Their high flexibility, robust insulation, and flame-retardant features make them a reliable choice for both stationary and mobile applications, ensuring operational safety and durability.

Versatile Applications and Configurations

You can employ these cables for a wide range of applications, including portable equipment, power tools, mobile machinery, and general wiring. Cores, colors, and lengths are customizable, enabling optimal configurations for even the most demanding requirements, while complying with international and Indian standards.

Safety, Compliance, and Easy Installation

Stringently manufactured according to standards like IS 9968 and IEC 60245, these cables deliver assured safety through superior dielectric strength and flame retardance. Their flexibility facilitates easy handling and installation, whether in tight-space industrial setups or extended outdoor runs.

FAQs of Elastomeric Cables:

Q: How are elastomeric cables different from standard PVC cables?

A: Elastomeric cables feature insulation and jackets made of high-performance elastomeric compounds like EPR, EPDM, or CSP, granting them superior flexibility and resistance to oils, chemicals, UV rays, and abrasiontraits not commonly matched by standard PVC cables.Q: What is the typical usage for these elastomeric cables?

A: These cables are ideal for industrial power transmission, mobile equipment, mining, drilling, welding, and portable machineryespecially where excellent flexibility, weather resistance, and robustness are critical.Q: When should I choose a halogen-free elastomeric cable option?

A: Halogen-free cables are preferred in environments where reducing toxic gas emissions during fire is essential, such as public places, transportation, or enclosed spaces, enhancing overall fire safety.Q: Where can I use these cables: indoors, outdoors, or both?

A: These cables are designed for both indoor and outdoor installations, withstanding UV exposure, weathering, and mechanical stress, making them suitable for varied environments from factories to mining sites.Q: What is the minimum bending radius for installation?

A: To maintain cable integrity during installation, a minimum bending radius of 6 times the outer diameter (OD) of the cable is recommended.Q: How do I order cables with specific lengths and packaging needs?

A: Elastomeric cables can be supplied in standard 100-meter coils or custom lengths as required, and are available in coils or wooden drums per your specifications at the time of ordering.Q: What are the main benefits of choosing elastomeric cables for industrial projects?

A: These cables provide high flexibility, superior mechanical and chemical resistance, enhanced safety through flame retardance and halogen-free options, easy installation, and compliance with major international standards, ensuring reliable and long-lasting performance in demanding settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Rubber Cables' category

Back to top